Bonded Abrasives Market Key Takeaways

- In 2024, Asia Pacific led the global market, capturing a dominant 55% share.

- North America is expected to register the highest growth rate over the forecast period.

- Europe continues to gain traction as a key regional market.

- The grinding wheels category accounted for a notable 52% share in 2024 among product types.

- The polishing wheels segment is projected to expand significantly in the coming years.

- The automotive sector emerged as the leading end-use segment with a 41% share in 2024.

- The aerospace industry is projected to witness substantial growth over the forecast timeline.

Market Overview

The bonded abrasives market is gaining significant traction across various industrial and manufacturing sectors due to its vital role in material removal, surface finishing, and precision shaping processes. Bonded abrasives are made by combining abrasive grains with a bonding material to form solid tools such as grinding wheels, cones, segments, and sticks. These tools are essential in industries such as automotive, aerospace, metal fabrication, construction, and general manufacturing. As industrial activity continues to expand globally, the bonded abrasives market is witnessing a surge in demand, driven by increased production volumes and the growing need for precision machining and durable tools.

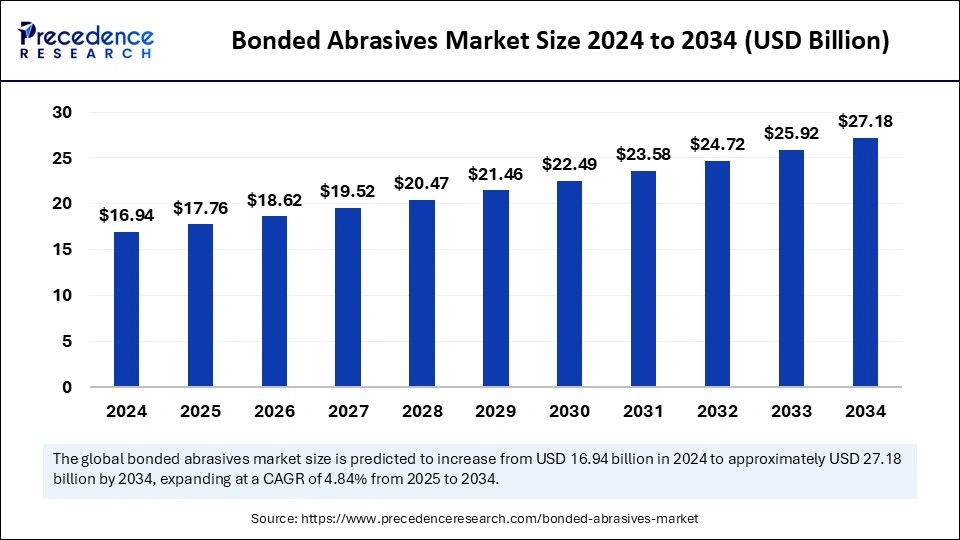

The global bonded abrasives market is experiencing growth due to rapid urbanization, rising infrastructure investments, and the automation of manufacturing processes. Companies are adopting advanced bonded abrasive solutions to meet the demand for high-speed material removal and improved efficiency. In 2024, the market size for bonded abrasives is estimated to have reached a significant valuation, and it is expected to grow steadily in the coming years, supported by innovation and increased industrial applications. As manufacturers invest in advanced grinding technologies, the bonded abrasives market is likely to continue evolving with more durable, efficient, and application-specific products.

Drivers

Several driving factors are contributing to the growth of the bonded abrasives market. One of the most prominent is the expansion of the automotive and aerospace industries. These sectors require high-precision machining for engine components, body parts, and metal fittings. Bonded abrasives are essential in grinding, deburring, and finishing metal surfaces, ensuring dimensional accuracy and smooth finishes. As vehicle production and aircraft assembly increase, the demand for high-performance bonded abrasives continues to rise.

Another significant driver for the bonded abrasives market is the global increase in construction and infrastructure projects. The need for cutting, grinding, and finishing tools in masonry, metalwork, and concrete preparation is leading to a higher uptake of bonded abrasives. These tools provide the strength and durability required to perform under harsh conditions while ensuring high productivity. Additionally, the rising demand for residential and commercial buildings in emerging economies supports sustained market growth.

The trend toward automation and smart manufacturing is also playing a key role in boosting the bonded abrasives market. Automated production lines require reliable abrasive tools capable of consistent performance. As smart manufacturing practices become more prevalent, companies are investing in high-quality bonded abrasives to reduce downtime, improve output quality, and meet tighter tolerances.

Opportunities

The bonded abrasives market is full of opportunities for growth and innovation. One of the most significant opportunities lies in the increasing adoption of superabrasive and high-performance bonded abrasive products. These advanced abrasives are designed for demanding applications that require superior hardness and extended life, such as grinding hard metals, ceramics, and composite materials. As industries evolve, the need for specialized solutions provides manufacturers with the chance to differentiate their product offerings and target niche markets.

Environmental sustainability is another area that presents opportunities in the bonded abrasives market. As industries aim to reduce their environmental impact, the demand for eco-friendly manufacturing processes and recyclable abrasives is increasing. Companies that develop sustainable bonded abrasives using low-emission binders and renewable materials stand to benefit from evolving regulatory standards and shifting consumer preferences.

The growing popularity of electric vehicles (EVs) also opens new avenues for the bonded abrasives market. EV production requires precise grinding and finishing of components like battery casings, drivetrains, and electric motors. Bonded abrasives provide the required accuracy and surface finish necessary in this high-growth sector. As EV adoption accelerates, manufacturers supplying bonded abrasives tailored to the needs of EV production will gain a competitive advantage.

Challenges

Despite its growth potential, the bonded abrasives market faces several challenges. One major concern is the volatility in raw material prices. Abrasive grains such as aluminum oxide, silicon carbide, and ceramic abrasives, along with bonding agents like resins and vitrified materials, are subject to price fluctuations due to global supply chain dynamics and geopolitical factors. This can affect the cost structure and profit margins of bonded abrasive manufacturers.

The bonded abrasives market is also challenged by intense competition. A large number of global and regional players compete in this space, offering a wide range of products with varying quality and pricing strategies. This competitive pressure can lead to pricing wars and reduced profitability for manufacturers, especially smaller firms that lack the economies of scale enjoyed by larger corporations.

Additionally, the market must address the challenge of balancing performance with safety. Bonded abrasives operate at high speeds and pressures, and improper usage can lead to serious accidents. This places an emphasis on the need for rigorous quality control and end-user training. Ensuring compliance with international safety standards and providing adequate user education are ongoing priorities for stakeholders in the bonded abrasives market.

Regional Insights

The bonded abrasives market exhibits diverse regional dynamics, with Asia Pacific emerging as the dominant force. In 2024, Asia Pacific held the largest market share, fueled by its strong manufacturing base and ongoing infrastructure development. Countries like China, India, Japan, and South Korea are home to numerous metalworking, automotive, and construction companies that rely heavily on bonded abrasives. The region’s low labor costs and government support for industrialization further boost demand for bonded abrasive products.

North America represents another important region for the bonded abrasives market. The United States and Canada have a well-established manufacturing ecosystem and a high adoption rate of automation and advanced machinery. The aerospace and automotive sectors in North America are significant consumers of bonded abrasives, with demand driven by precision grinding needs and the emphasis on high-quality production standards.

Europe also plays a key role in the bonded abrasives market, particularly due to its focus on innovation and sustainability. Germany, France, Italy, and the United Kingdom are home to leading automotive and machinery manufacturers that use bonded abrasives for grinding and polishing applications. The European market is characterized by a strong emphasis on product quality, worker safety, and environmentally friendly practices, which influences the development and selection of bonded abrasive products.

In Latin America and the Middle East & Africa, the bonded abrasives market is gaining momentum due to increased industrial activity and infrastructure development. While these regions are still developing compared to Asia Pacific or North America, rising investments in manufacturing and construction sectors are gradually boosting demand for bonded abrasives. These emerging markets offer promising growth potential, particularly for manufacturers willing to invest in local partnerships and distribution networks.

Recent Developments

The bonded abrasives market has seen a wave of innovation and strategic expansion in recent years. Manufacturers are investing in R&D to develop new products that offer higher efficiency, longer tool life, and enhanced safety features. One notable trend is the increasing use of vitrified and resin bonds with improved thermal resistance and durability, which are suitable for high-speed grinding operations. These innovations are helping to expand the application scope of bonded abrasives.

Digitalization and Industry 4.0 are also influencing the bonded abrasives market. Smart abrasive solutions equipped with sensors and monitoring technologies are being introduced to help optimize grinding performance and reduce operational downtime. These advanced abrasives can provide real-time data on temperature, vibration, and wear patterns, enabling predictive maintenance and process control in manufacturing environments.

Strategic collaborations and mergers have become common in the bonded abrasives market as companies aim to expand their geographic reach and strengthen their product portfolios. For instance, leading manufacturers are partnering with local distributors and OEMs to penetrate emerging markets and build brand recognition. Such collaborations enable companies to better serve customers with localized solutions and quicker delivery timelines.

Sustainability initiatives are also shaping the bonded abrasives market. Several manufacturers are focusing on reducing the environmental impact of their products by introducing recyclable abrasives and using low-emission bonding materials. These initiatives not only help in meeting regulatory standards but also appeal to environmentally conscious customers.

Bonded Abrasives Market Companies

- Nippon Resibon Corporation

- Carborundum Universal Limited

- Buffalo Abrasives

- Abrasives Manhattan

- Marrose Abrasives

- Grinding Techniques Ltd

- SAK Abrasives Limited

- Sia Abrasives Industries AG

- Flexovit

- Saint-Gobain

Segments Covered in the Market

By product type

- Grinding wheels

- Cutting wheels

- Polishing wheels

- Other product types

By end use

- Automotive

- Aerospace

- Metalworking

- Other end uses

By region

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa

Ready for more? Dive into the full experience on our website!