Cold Spray Technology Market Key Takeaways

- North America dominated the global market with the largest market share of 42% in 2023.

- Asia Pacific is anticipated to grow at the fastest CAGR during the forecast period.

- By material, the aluminum segment contributed the highest market share of 29% in 2023.

- By material, the titanium segment is expected to grow at the fastest CAGR over the forecast period.

- By service, the cold spray coatings segment captured the biggest market share of 90% in 2023.

- By service, the cold spray additive manufacturing (CSAM) segment is anticipated to grow at the fastest CAGR from 2024 to 2034.

- By end use, in 2023, the aerospace segment generated the major market share of 27% in 2023.

- By end use, the electrical and electronics segment is estimated to grow rapidly during the forecast period.

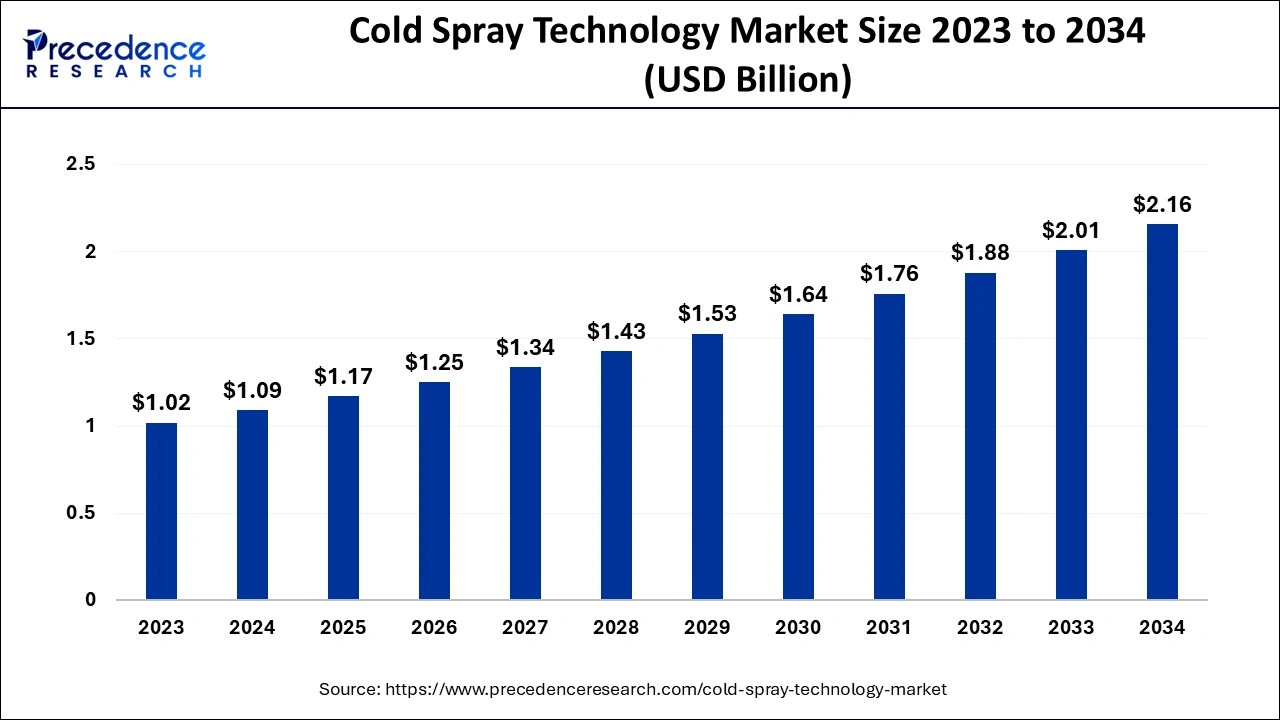

Market Overview

The cold spray technology market has been experiencing rapid evolution as industries seek innovative surface engineering solutions that minimize thermal distortion and oxidation. Cold spray, a solid-state process, allows metal coatings to be applied at high velocity without melting the material, making it ideal for sensitive applications.

This market has been gaining momentum due to the growing demand for advanced repair technologies, particularly in the aerospace, automotive, and defense sectors. Its ability to extend the lifespan of components and reduce maintenance costs positions it as a preferred alternative to traditional thermal spray methods.

Drivers

One of the primary drivers of the cold spray technology market is the increasing investment in aerospace maintenance, repair, and overhaul (MRO). As airlines aim to reduce operating costs and prolong fleet lifecycles, cold spray provides a cost-effective and reliable solution. Furthermore, the automotive sector’s pursuit of lightweight and corrosion-resistant materials is fueling adoption.

Technological advancements in cold spray systems, including portable and automated units, are also propelling market growth by making the technology more accessible across industrial settings.

Opportunities

The cold spray technology market presents significant growth opportunities, particularly in the energy and electronics industries. As manufacturers look for non-destructive, precise coating technologies to enhance component durability, cold spray becomes a compelling choice. Emerging markets, especially in Asia-Pacific and Latin America, are showing strong interest due to expanding industrial bases and infrastructure investments.

Additionally, ongoing research in additive manufacturing is opening doors for cold spray to play a pivotal role in 3D printing of metal components.

Challenges

Despite its advantages, the cold spray technology market faces several challenges that may hinder widespread adoption. High initial capital investment for equipment and the need for skilled technicians can be barriers for small and mid-sized enterprises.

The technology’s limitations in terms of coating certain complex geometries and materials also pose constraints. Moreover, a lack of standardized protocols and limited awareness among potential end users further restricts market penetration.

Regional Insights

North America currently leads the cold spray technology market driven by a strong aerospace and defense manufacturing base and active government support for advanced materials research. Europe follows closely, with emphasis on sustainability and innovation in automotive and industrial sectors.

The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, rising defense budgets, and increased investments in infrastructure projects in countries such as China, India, and South Korea.

Recent Developments

Recent developments in the Cold Spray Technology Market include strategic collaborations between equipment manufacturers and research institutions aimed at enhancing process efficiency and expanding application areas. Notably, several companies are introducing hybrid systems that integrate cold spray with other surface treatment methods for better material performance.

Advancements in computer-aided spray design and robotic integration are also improving coating accuracy and repeatability, setting the stage for further adoption in high-precision industries.

Cold Spray Technology Market Companies

- ASB Industries (Hannecard Roller Coatings, Inc)

- Bodycote plc

- Flame Spray Technologies BV

- Plasma Giken Co., Ltd.

- VRC Metal Systems

- CenterLine (Windsor) Limited

- WWG Engineering Pte. Ltd.

- Praxair S.T. Technology, Inc.

- Impact Innovations GmbH

- Concurrent Technologies Corporation

- Effusiontech Pty Ltd (SPEE3D)

- Titomic Limited

Segments Covered in the Report

By Material

- Nickel

- Copper

- Aluminum

- Titanium

- Magnesium

- Others

By Service

- Cold Spray Additive Manufacturing

- Cold Spray Coatings

By End-Use

- Aerospace

- Automotive

- Defense

- Electrical and Electronics

- Utility

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa