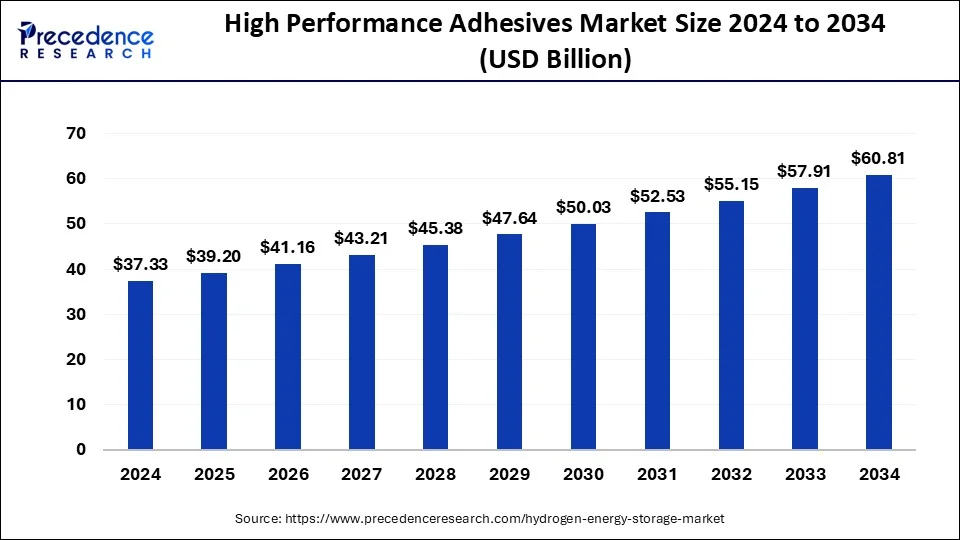

The high-performance adhesives market is expected to grow from USD 37.33 billion in 2024 to USD 60.81 billion by 2034, registering a CAGR of 5%.

High Performance Adhesives Market Key Takeaways

- Asia Pacific dominated the high-performance adhesives market with a 44% share in 2023.

- The epoxy segment accounted for the largest product share in 2023.

- The solvent-based technology segment generated the highest revenue share in 2023.

- The medical segment is projected to witness the fastest growth during the forecast period.

Market Overview

The high performance adhesives market is witnessing significant growth due to the increasing demand for strong bonding materials in various industries. These adhesives provide superior bonding strength, durability, and resistance to extreme environmental conditions, making them ideal for use in automotive, aerospace, electronics, and healthcare applications. High performance adhesives are used to bond materials that require high load-bearing capacity and resistance to heat, chemicals, and pressure. The rising trend of lightweight materials in automotive and aerospace sectors, along with the growing need for miniaturization in electronics, is driving the demand for these adhesives. Moreover, advancements in adhesive technologies, such as hybrid adhesives and bio-based alternatives, are expanding the application scope of high performance adhesives.

Drivers

- Rising Demand from Automotive and Aerospace Industries

The growing automotive and aerospace sectors are major drivers of the high performance adhesives market. These adhesives are extensively used to bond lightweight materials such as composites, aluminum, and plastics, reducing the overall weight of vehicles and aircraft. This contributes to enhanced fuel efficiency and lower emissions, aligning with global sustainability goals. - Growing Application in Electronics and Medical Devices

High performance adhesives are increasingly used in electronic devices and medical equipment due to their ability to withstand high temperatures, vibrations, and harsh environmental conditions. The expanding consumer electronics market and the rising demand for medical devices, particularly post-pandemic, are fueling market growth. - Advancements in Adhesive Technologies

Continuous research and development efforts have led to the introduction of innovative adhesive formulations with improved bonding capabilities, durability, and environmental sustainability. Hybrid adhesives that combine the benefits of different adhesive types are gaining traction, driving market expansion.

Opportunities

- Expansion in Renewable Energy Sector

The increasing adoption of renewable energy sources such as wind and solar power presents lucrative opportunities for high performance adhesives. These adhesives are used in the assembly of wind turbine blades, solar panels, and other renewable energy components, ensuring structural integrity and long-lasting performance. - Growing Demand for Bio-Based and Sustainable Adhesives

With the rising focus on environmental sustainability, the development and adoption of bio-based high performance adhesives derived from renewable sources are expected to create new growth avenues. These adhesives reduce carbon emissions and comply with stringent environmental regulations, catering to the growing demand for eco-friendly solutions. - Emerging Applications in 3D Printing and Additive Manufacturing

The increasing use of 3D printing technology in various industries opens up opportunities for high performance adhesives. These adhesives play a crucial role in bonding 3D-printed parts and ensuring structural stability, enabling the production of complex and customized components.

Challenges

- Stringent Regulatory Standards

The high performance adhesives market is subject to stringent regulations regarding the use of chemicals and volatile organic compounds (VOCs). Compliance with environmental and safety standards increases production costs and poses challenges for manufacturers. - High Production Costs and Raw Material Prices

The manufacturing of high performance adhesives involves high costs due to the use of advanced raw materials and complex production processes. Fluctuations in the prices of raw materials, such as resins and polymers, further add to the challenges faced by manufacturers. - Limited Awareness and Adoption in Emerging Markets

Despite their benefits, high performance adhesives are not widely adopted in emerging markets due to a lack of awareness and technical expertise. Limited knowledge about the advantages and applications of these adhesives hinders market penetration in developing regions.

Regional Insights

- North America

North America leads the high performance adhesives market due to the strong presence of automotive, aerospace, and electronics industries. The region’s focus on adopting advanced technologies and sustainable solutions is driving the demand for high performance adhesives. - Europe

Europe is a prominent market for high performance adhesives, driven by stringent environmental regulations and increasing demand for eco-friendly adhesives. The region’s focus on renewable energy projects and automotive innovations further supports market growth. - Asia Pacific

Asia Pacific is expected to witness the fastest growth in the high performance adhesives market. Rapid industrialization, infrastructure development, and the booming electronics and automotive sectors in countries such as China, India, and Japan contribute to market expansion. - Latin America and Middle East & Africa

These regions are gradually emerging as potential markets for high performance adhesives, driven by growth in construction, automotive, and energy sectors. However, challenges such as limited technical expertise and lower awareness may slow down market penetration.

Recent News

- Introduction of Bio-Based Adhesives by Leading Manufacturers

Several adhesive manufacturers have launched bio-based high performance adhesives to meet the growing demand for sustainable solutions. These adhesives are gaining popularity across various industries due to their reduced environmental impact. - Strategic Collaborations and Acquisitions to Expand Market Presence

Key players in the market are engaging in strategic collaborations and acquisitions to strengthen their market position and expand their product portfolios. These initiatives are expected to drive innovation and growth in the high performance adhesives market.

High Performance Adhesives Market Companies

- 3M

- Sika AG

- B. Fuller Company.

- Bostik

- Pidilite Industries Limited

- Engineered Bonding Solution

- Anabond

- Huntsman International LLC.

- Ashland

- Henkel

- Permabond LLC

- Delo Industrial Adhesives, LLC

- WEICON GmbH & Co.KG

- Gougeon Brothers

- Royal Adhesives & Sealants, LLC

- Ashland Inc

- Hernon Manufacturing

Segments Covered in the Report

By Technology

- Solvent based

- Hot melt

- Water based

- Reactive & others

By Product

- Polyurethane

- Silicone

- Epoxy

- Acrylic

- Others

By End-User

- Electrical & electronics

- Packaging

- Medical

- Transportation

- Construction

- Others

By Geography

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia Pacific

- China

- India

- Japan

- South Korea

- Middle East & Africa

- Latin America

Ready for more? Dive into the full experience on our website!

https://www.precedenceresearch.com/