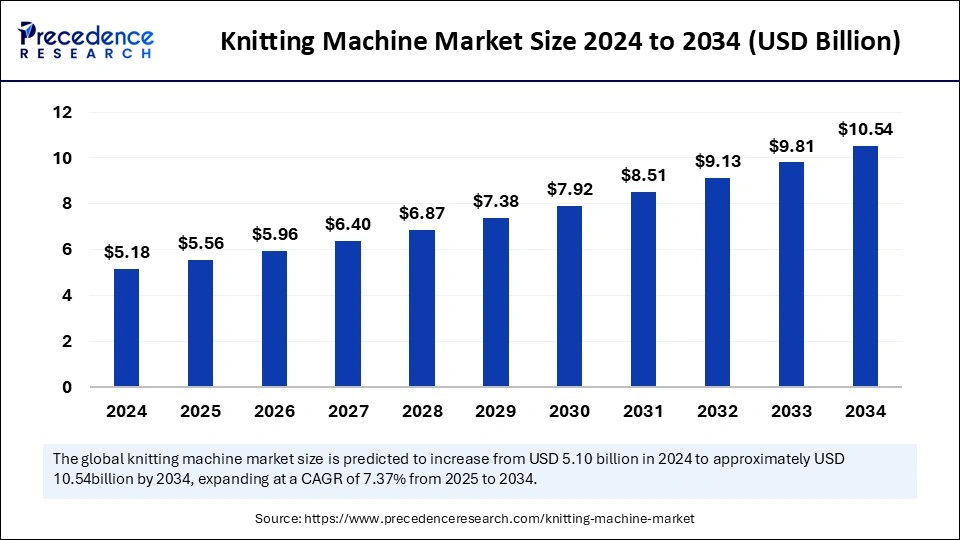

Knitting machine market is projected to grow from USD 5.18 billion in 2024 to USD 10.54 billion by 2034, at a CAGR of 7.37%.

Knitting Machine Market Key Takeaways

- Asia Pacific dominated the global market with the largest market share of 41% in 2024.

- North America will expand at the fastest CAGR in the market between 2025 and 2034.

- By type, the weft-knitting machine system segment held the largest market share in 2024.

- By type, the warp-knitting machines segment is anticipated to grow at a remarkable CAGR between 2025 and 2034.

- By knit type, the double-knit segment captured the biggest market share in 2024.

- By knit type, the single knit segment is expected to expand at a notable CAGR over the projected period.

- By mode of operation, the fully automatic segment captured the biggest market share in 2024.

- By mode of operation, the semi-automatic segment is expected to expand at a notable CAGR over the projected period.

- By end-use, the apparel textiles segment generated the major market share in 2024.

- By end-use, the sports textiles segment is expected to grow notably over the projected period.

- By distribution channel, the direct sales segment has held the largest market share in 2024.

- By distribution channel, the indirect sales segment is expected to grow the fastest throughout the forecast period.

Knitting Machine Market Overview

The Knitting Machine Market is evolving rapidly with the integration of advanced technologies such as automation, IoT, and artificial intelligence (AI) in textile manufacturing. Knitting machines, which produce various knitted fabrics by interlocking loops of yarn, are now equipped with smart sensors, digital controls, and pattern management systems that enhance operational efficiency. The market encompasses a wide range of machines, including weft-knitting machines, warp-knitting machines, and circular knitting machines, each catering to diverse textile applications.

The adoption of fully automatic and semi-automatic knitting machines is reducing manual labor dependency while ensuring high-precision output. Furthermore, the demand for customized and on-demand textile production is driving the adoption of flexible knitting machines capable of producing intricate patterns, complex designs, and seamless garments. As fashion trends shift toward personalization and sustainability, manufacturers are investing in innovative knitting solutions that align with these emerging market dynamics.

Knitting Machine Market Drivers

-

Integration of Automation and Artificial Intelligence

Advanced knitting machines equipped with AI and automation technologies are revolutionizing fabric production by minimizing errors, reducing wastage, and improving design accuracy. These technologies enable real-time monitoring and quality control, enhancing overall productivity. -

Growing Demand for High-Speed Circular and Flatbed Knitting Machines

The increasing demand for high-speed circular and flatbed knitting machines is driving market growth, especially in large-scale textile production. These machines offer enhanced efficiency, reduced production time, and the ability to produce a wide range of textile products. -

Advancements in 3D and Seamless Knitting Technologies

The rise of 3D and seamless knitting technologies is creating new possibilities for producing complex fabric structures with minimal waste. These technologies enable the development of garments with enhanced functionality and durability, driving adoption across various applications.

Knitting Machine Market Opportunities

-

Adoption of IoT-Enabled Knitting Systems

The integration of IoT in knitting machines is enabling real-time data monitoring, predictive maintenance, and remote troubleshooting. This presents an opportunity for manufacturers to offer smart knitting solutions that optimize production processes. -

Emergence of Sustainable Textile Technologies

The demand for sustainable textiles is driving interest in knitting machines that can produce eco-friendly fabrics from recycled and biodegradable fibers. Manufacturers can capitalize on this trend by developing knitting technologies that support sustainable practices. -

Expansion of Digital Textile Printing and Knitting Integration

The convergence of digital textile printing and knitting technologies is creating opportunities for innovative fabric design and pattern creation. Knitting machine manufacturers can explore collaborations with digital printing companies to offer integrated solutions.

Market Challenges

-

Technical Complexity in Upgrading Legacy Systems

Upgrading legacy knitting systems to incorporate advanced technologies requires technical expertise and significant investment. The complexity of integrating new technologies into existing systems poses a challenge for manufacturers. -

High Initial Setup and Maintenance Costs

Advanced knitting machines with automation and IoT capabilities entail high initial investment and maintenance costs. Small and medium-sized enterprises may find it challenging to adopt such technologies due to budget constraints. -

Risk of Downtime and Production Disruptions

Highly automated knitting systems are vulnerable to downtime and operational disruptions if maintenance and system upgrades are not conducted regularly. Ensuring system reliability is essential to mitigate this risk.

Knitting Machine Market Regional Insights

-

Asia Pacific

Asia Pacific is the leading region in the knitting machine market, with countries such as China, India, and Vietnam driving growth. The region’s strong presence in textile manufacturing and increasing adoption of automated systems contribute to market expansion. -

Europe

Europe is witnessing steady growth in the knitting machine market, driven by increasing demand for technical textiles and innovations in textile machinery. Countries such as Germany and Italy are at the forefront of technological advancements. -

North America

North America is adopting advanced knitting technologies to meet the growing demand for functional textiles and personalized garments. The region’s focus on sustainable textile production is boosting market growth.

Knitting Machine Market Recent Developments

-

Introduction of Smart Knitting Machines with AI Integration

Leading manufacturers are introducing smart knitting machines equipped with AI and IoT capabilities to enhance productivity and reduce operational downtime. -

Strategic Collaborations for Seamless Textile Production

Key players are forming strategic partnerships to develop seamless textile production technologies, catering to the growing demand for high-performance fabrics. -

Expansion of Digital Textile Printing and Knitting Facilities

Market players are expanding their digital textile printing and knitting facilities to cater to the rising demand for customized and eco-friendly fabrics.

Knitting Machine Market Companies

- Flying Tiger

- Fukuhara

- Hanma group

- Jingwei Textile Machinery

- Lamb

- Lisky

- Mayer and CIE

- Orizio

- Pai Lung

- Santoni

- Shima Seiki

- Stoll

- Tompkins

- Yamato Sewing Machine

- Zentex

Segments Covered in the Report

By Type

- Warp knitting machines

- Raschel warp

- Tricot warp

- Others (crochet, etc.)

- Weft knitting machines

- Circular

- Straight bar

- Others (loop wheel, etc.)

By Knit Type

- Single knit

- Double knit

By Mode of Operation

- Manual

- Semi-automatic

- Fully automatic

By End Use

- Automotive textiles

- Sports textiles

- Apparel textiles

- Home textiles

- Others (footwear industry, etc.)

By Distribution Channel

- Direct sales

- Indirect sales

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Ready for more? Dive into the full experience on our website!