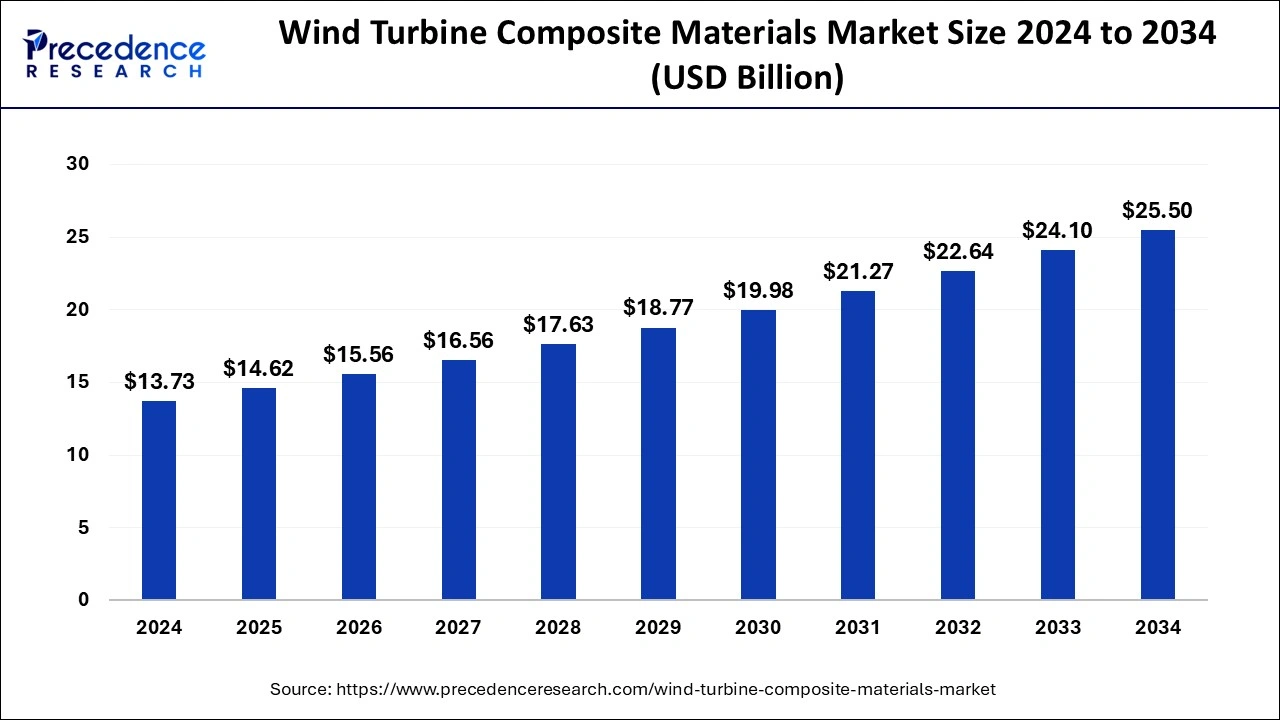

The global wind turbine composite materials market size accounted for USD 12.90 billion in 2023 and is predicted to rake around USD 24.10 billion by 2033, growing at a CAGR of 6.44% from 2024 to 2033.

Key Points

- Asia Pacific dominated the market in 2023 with the largest share 35%.

- North America is anticipated to grow at a notable growth rate in the wind turbine composite materials market during the forecast period.

- By fiber type, the glass fiber segment held the largest share of around 65% in 2023.

- By fiber type, the carbon fiber segment is expected to grow significantly during the forecast period.

- By technology, the vacuum injection molding segment accounted for the dominating share of 45% in 2023.

- By technology, the prepreg segment is observed to witness a considerable growth rate in the global wind turbine composite materials market over the forecast period.

- By application, the wind blades segment held the dominating share of 75% in 2023.

Wind turbine composite materials play a pivotal role in the construction and performance of modern wind turbines. These materials, composed primarily of fiberglass, carbon fiber, and resin, offer numerous advantages over traditional materials like steel or aluminum. The unique properties of composite materials make them ideal for use in wind turbine blades, towers, and other structural components, contributing to the efficiency, durability, and sustainability of wind energy generation.

Get a Sample: https://www.precedenceresearch.com/sample/4067

One of the key advantages of using composite materials in wind turbines is their exceptional strength-to-weight ratio. Compared to steel or aluminum, composites are significantly lighter while maintaining high tensile strength and stiffness. This lightweight characteristic enables the construction of longer wind turbine blades, which can capture more wind energy and increase the overall efficiency of the turbine. Additionally, lighter components reduce the structural load on the turbine tower, foundation, and other support structures, leading to cost savings and simplified installation processes.

Wind Turbine Composite Materials Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2033 | CAGR of 6.44% |

| Global Market Size in 2023 | USD 12.90 Billion |

| Global Market Size in 2024 | USD 13.73 Billion |

| Global Market Size by 2033 | USD 24.10 Billion |

| Largest Market | Asia-Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | By Fiber Type, By Technology, and By Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Moreover, wind turbine composite materials offer superior corrosion resistance and fatigue performance compared to traditional materials. Steel structures are susceptible to corrosion in harsh environmental conditions, leading to maintenance challenges and reduced lifespan. In contrast, composite materials are inherently resistant to corrosion, making them ideal for offshore wind farms and other coastal applications where exposure to saltwater and moisture is prevalent. Furthermore, composites exhibit excellent fatigue resistance, allowing wind turbine blades to withstand prolonged exposure to cyclic loading without compromising structural integrity or performance.

Another significant advantage of wind turbine composite materials is their design flexibility and versatility. Composites can be molded into complex shapes and customized to meet specific performance requirements, allowing engineers to optimize blade geometry, aerodynamics, and structural properties for maximum energy capture and efficiency. Advanced manufacturing techniques such as automated fiber placement and resin infusion enable the production of seamless, high-quality composite components with tight tolerances and consistent material properties. This flexibility in design and manufacturing facilitates innovation and optimization in wind turbine technology, driving improvements in performance and reliability.

Furthermore, wind turbine composite materials contribute to environmental sustainability by reducing the carbon footprint of wind energy generation. The manufacturing process for composite materials consumes less energy and generates fewer greenhouse gas emissions compared to traditional materials like steel or aluminum. Additionally, the lightweight nature of composites reduces transportation and installation costs, further minimizing the environmental impact of wind turbine projects. As the demand for clean, renewable energy sources continues to grow, the use of composite materials in wind turbines offers a sustainable solution to meet energy needs while mitigating climate change and reducing reliance on fossil fuels.

Read Also: Data Center Transformation Market Size, Share, Report by 2033

Recent Developments

- According to a BSE filing, in June 2023, SJVN Green Energy, a subsidiary of SJVN Ltd, secured a 200 MW wind power project through a tariff-based competitive bidding process conducted by the Solar Energy Corporation of India. This project requires an investment of Rs 1,400 crore. SJVN Green Energy will undertake the development of this wind power project anywhere in India through an EPC (engineering procurement construction) contract.

- Amazon now has more than 500 wind and solar projects globally, and once operational, they are expected to generate more than 77,000 gigawatt-hours (GWh) of clean energy each year, or enough to power 7.2 million U.S. homes.

Wind Turbine Composite Materials Market Companies

- TPI Composites Inc.

- Huntsman International LLC

- Teijin Limited

- TPI Composites Inc.

- LM Wind Power

- Suzlon Energy Limited

- Gurmit Holding AG

- LM Wind Power

- Molded Fiber Glass Companies

- Toray Industries, Inc.

- Vestas Wind Systems A/S

- Siemens Gamesa Renewable Energy, S.A.U.

- Hexcel Corporation

- Lianyungang Zhongfu Lianzhong Composites Group Co. Ltd

- Others

Segments Covered in the Report:

By Fiber Type

- Glass Fiber

- Carbon Fiber

- Others

By Technology

- Vacuum Injection Molding

- Prepreg

- Hand Lay-Up

- Others

By Application

- Wind blades

- Nacelles

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/

Blog: https://www.dailytechbulletin.com/

Blog: https://www.autoindustrybulletin.com/