X-Ray Inspection System Market Key Takeaways

X-Ray Inspection System Market Key Takeaways- North America dominated the global market with the largest market share of 37% 2024.

- Asia Pacific is estimated to expand the fastest CAGR in the market between 2025 and 2034.

- Europe has been witnessing notable growth in the global market.

- By technology, the digital imaging segment held the largest market share in 2024.

- By technology, the film-based imaging segment is anticipated to grow at a remarkable CAGR between 2025 and 2034.

- By dimension, the 2D X-ray segment contribute the biggest market share in 2024.

- By dimension, the 3D X-ray segment is anticipated to grow at a remarkable CAGR between 2025 and 2034.

- By end-user, the manufacturing segment captured the highest market share in 2024.

- By end-user, the aerospace segment is anticipated to grow at a remarkable CAGR between 2025 and 2034.

Market Overview

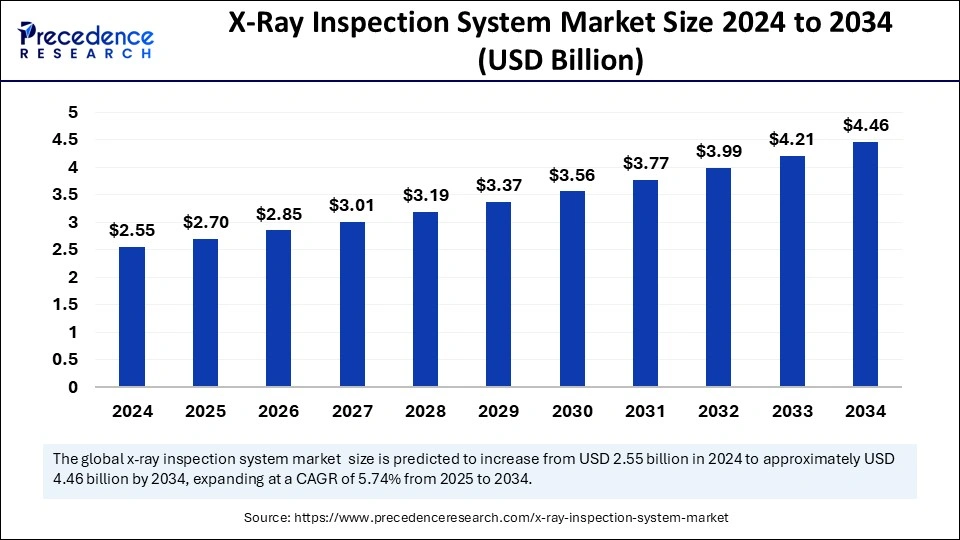

The X-ray inspection system market has grown into a critical part of quality control, security screening, and non-destructive testing across diverse industries. These systems use high-energy radiation to inspect internal structures and defects without altering the physical integrity of the object. As industries like food and beverage, automotive, electronics, and pharmaceuticals demand more reliable, fast, and precise quality assurance tools, the X-ray inspection system market continues to expand. With regulatory compliance becoming increasingly stringent and automation gaining momentum, these systems are becoming indispensable for both safety and efficiency.

Drivers

A significant driver of the X-ray inspection system market is the growing emphasis on product quality, especially in highly regulated sectors such as pharmaceuticals and food processing. Manufacturers are increasingly investing in X-ray technology to detect contaminants, evaluate packaging integrity, and comply with safety standards. Additionally, the rising demand for high-performance electronic components is pushing the semiconductor and automotive sectors to adopt advanced X-ray systems for defect analysis and process validation. Technological improvements such as real-time imaging, AI-based defect recognition, and portable units are further propelling adoption across verticals.

Opportunities

The X-ray inspection system market presents notable opportunities through innovation in digital imaging and machine learning integration. These technologies can help develop smart inspection systems that automatically classify defects and improve inspection speed and accuracy. There is also growing potential in emerging economies where industrial automation and export-oriented production are accelerating. Expansion into smaller-scale manufacturing facilities with cost-effective, compact X-ray solutions also represents a key growth area. Moreover, the increasing use of these systems in additive manufacturing and 3D printing provides new applications for structural verification.

Challenges

Despite strong growth, the X-ray inspection system market faces several challenges. High initial costs and maintenance requirements can deter adoption among small and mid-sized enterprises. Radiation safety concerns and strict regulatory frameworks around the use of ionizing equipment add complexity to deployment, particularly in non-industrial environments. Additionally, skilled personnel are required to operate and interpret results accurately, which limits widespread use in certain regions. System integration into legacy manufacturing setups can also be difficult, requiring significant process reengineering and infrastructure upgrades.

Regional Insights

North America remains a leading region in the X-ray inspection system market due to its well-established food processing, aerospace, and medical device industries. The United States is particularly advanced in adopting automated quality control systems, boosting demand for high-performance X-ray units. Europe follows closely, with Germany, the UK, and France driving innovation in automotive and pharmaceutical applications. The Asia-Pacific region is experiencing rapid growth, with China, Japan, and South Korea investing in manufacturing upgrades and infrastructure development. Latin America and the Middle East are also showing emerging demand, particularly in food safety and border security.

Recent Developments

Recent developments in the X-ray inspection system market include the introduction of AI-powered systems capable of identifying a broader range of defects with improved speed and minimal human intervention. Companies are increasingly launching compact and mobile solutions suitable for on-site inspections. The integration of cloud-based analytics and data storage is enhancing traceability and remote access capabilities. Partnerships between inspection system manufacturers and automation technology firms are facilitating the development of turnkey solutions for factory-wide implementation. Furthermore, new safety enhancements and compliance certifications are enabling expanded use in sensitive sectors like healthcare and aviation.

X-Ray Inspection System Market Companies

- North Star Imaging Inc.

- Nikon Metrology, Inc.

- Nordson Corporation

- YXLON International GmbH

- VJ Group, Inc.

- Mettler Toledo International Inc.

- Ametek, Inc.

- Viscom AG

- ViTrox Corporation Berhad

- Test Research, Inc.

Segments Covered in the Report

By Technology

- Digital Imaging

- Film-based imaging

By Dimension

- 2D

- 3D

By End Use

- Manufacturing

- Oil and Gas

- Aerospace

- Automotive

- Others

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa